Hydronic Underfloor Heating Technology represents a quiet revolution in the way buildings are heated. Instead of relying on convective airflows or point-source radiators, hydronic systems distribute warmth through water circulating beneath the floor surface. The result is not merely heat, but thermal equilibrium—an even, immersive comfort that aligns with both human physiology and modern energy-efficiency goals.

At its core, hydronic underfloor heating uses low-temperature water, typically between 30–50°C, flowing through a network of pipes embedded within or beneath the floor. This system transforms the entire floor into a radiant heat emitter. Unlike traditional systems that concentrate warmth near walls or ceilings, radiant floor heating delivers energy where it is most effective: at ground level, where occupants live and move.

This Hydronic Underfloor Heating Technology has matured significantly over recent decades. What was once a niche solution for luxury homes is now a mainstream option for residential, commercial, and institutional buildings worldwide.

The Science Behind Hydronic Radiant Heating

Hydronic systems operate on the principle of radiant heat transfer. Rather than heating air directly, energy radiates upward from the warm floor, gently warming objects and people in the room. This method reduces stratification, minimizes heat loss, and improves perceived comfort at lower air temperatures.

Hydronic Underfloor Heating Technology, Water acts as an exceptionally efficient heat transfer medium. Compared to air-based systems, hydronic heating can transport more thermal energy using less energy input. This efficiency explains why hydronic underfloor heating is often paired with renewable or low-carbon heat sources.

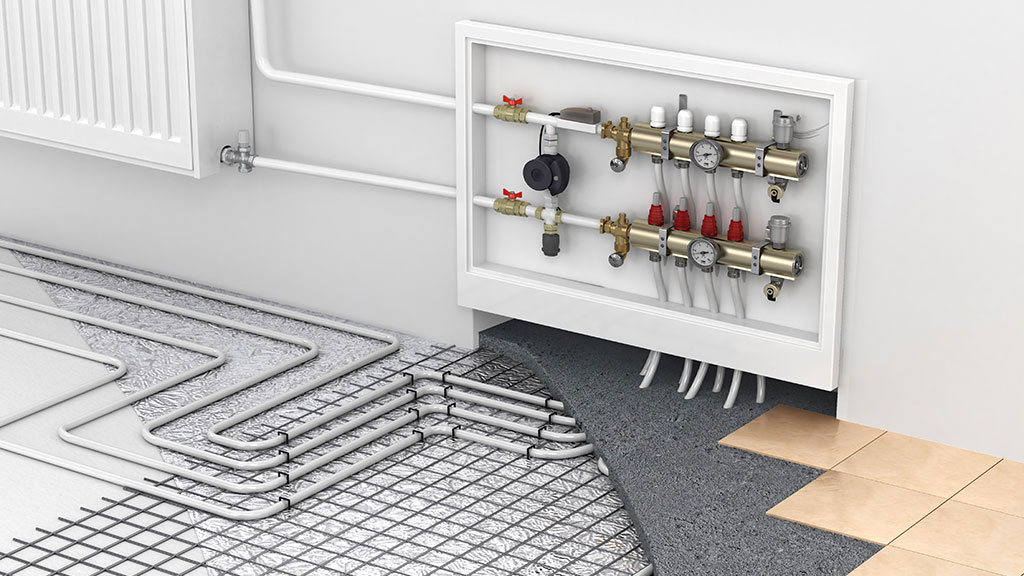

The hydronic underfloor heating technology system typically consists of cross-linked polyethylene (PEX) or multilayer composite pipes, manifolds, circulation pumps, controls, and a heat source. Each component is optimized to work in harmony, creating a responsive and durable heating solution.

System Architecture and Core Components

Hydronic Underfloor Heating Technology is a modern hydronic installation modular by design. The pipework is laid in loops, each connected to a central manifold that regulates flow and temperature. Zoning is easily implemented, allowing different rooms or areas to operate independently.

Advanced control systems enable precise thermal management. Digital thermostats, weather compensation controls, and smart home integration allow real-time optimization. This precision is particularly valuable in climates with variable temperature profiles.

Hydronic Underfloor Heating Technology the manifold acts as the system’s nervous system. Flow meters, balancing valves, and actuators ensure each loop receives the appropriate amount of heat. This level of control distinguishes hydronic systems from simpler heating methods. https://www.centralheating.co.nz/assets/resources/Intro-to-Hydronic-Underfloor-Heating.pdf

Hydronic Underfloor Heating Installation Process

Hydronic underfloor heating installation requires careful planning and professional execution. The process begins with a thermal assessment of the building to determine heat loads, insulation requirements, and zoning strategy.

Pipework is then installed using one of several methods:

- Embedded in concrete slabs for new builds

- Laid within screed for retrofits

- Installed in modular panels for timber or lightweight floors

Once installed, the system undergoes pressure testing before the floor finish is applied. This ensures long-term reliability and leak prevention. Commissioning includes balancing flows, calibrating controls, and verifying thermal performance.

While installation complexity exceeds that of conventional radiators, the long-term benefits often justify the initial effort.

Compatibility With Different Floor Types

Hydronic systems are remarkably versatile. Hydronic underfloor heating timber floors are particularly popular due to the aesthetic appeal of natural materials combined with radiant comfort.

Engineered timber is generally preferred over solid hardwood, as it offers greater dimensional stability under temperature variation. Proper design ensures surface temperatures remain within safe limits, preventing warping or shrinkage.

Tile, stone, and polished concrete are ideal companions to hydronic heating due to their high thermal conductivity. Carpet can also be used, provided the combined tog rating does not impede heat transfer excessively.

Hydronic Underfloor Heating Cost Considerations

The question of hydronic underfloor heating cost is multifaceted. Initial expenses are higher than traditional heating systems, reflecting material, labor, and design complexity. However, cost analysis must extend beyond installation.

Operating costs are typically lower due to improved efficiency and compatibility with low-temperature heat sources. Over the system’s lifespan, energy savings can offset upfront investment.

Factors influencing cost include:

- Building size and layout

- Floor construction type

- Heat source selection

- Level of zoning and control

When evaluating hydronic underfloor heating technology cost, it is essential to consider long-term value rather than short-term expenditure. https://www.danfoss.com/en/products/dhs/hydronic-underfloor-heating

Heat Sources and System Integration

One of the defining strengths of hydronic systems is flexibility in heat generation. Hydronic Underfloor Heating Technology heat pump integration is increasingly common, particularly air-source and ground-source heat pumps.

Heat pumps operate most efficiently at low flow temperatures, making them an ideal match for underfloor heating. This synergy significantly reduces carbon emissions and operating costs compared to fossil fuel boilers.

Hydronic Underfloor Heating Technology other compatible heat sources include gas boilers, biomass systems, and solar thermal collectors. Hybrid systems can further enhance resilience and efficiency.

Hydronic Floor Heating Pros and Cons

Evaluating Hydronic Underfloor Heating Technology pros and cons requires a balanced perspective.

Advantages include:

- Exceptional thermal comfort

- Reduced energy consumption

- Invisible heating infrastructure

- Improved indoor air quality

Challenges include:

- Higher initial installation cost

- Longer response time compared to radiators

- Complex retrofitting in existing buildings

For many users, the advantages outweigh the limitations, particularly in well-insulated buildings designed for low-temperature heating.

Performance in Different Climates

Hydronic underfloor heating performs effectively across a wide range of climates. In colder regions, continuous low-level heating maintains consistent comfort without dramatic temperature swings. In milder climates, systems can operate intermittently, delivering efficiency without excess energy use.

In Australia, demand has increased significantly. Hydronic underfloor heating Sydney installations are becoming more common as homeowners seek efficient winter heating without compromising interior design. When paired with renewable energy, these systems align with sustainability targets and rising energy costs.

Energy Efficiency and Sustainability

Radiant heating systems inherently support energy efficiency. Lower operating temperatures reduce thermal losses, while even heat distribution minimizes overcompensation.

Hydronic systems are particularly well-suited to low-energy buildings and passive house designs. When combined with renewable heat sources, they contribute to substantial reductions in greenhouse gas emissions.

Lifecycle assessments often reveal hydronic heating to be among the most sustainable heating options available, especially when longevity and operational efficiency are considered.

Maintenance and Longevity

Properly installed hydronic systems are renowned for durability. Pipework embedded in floors is typically rated for several decades of service. Maintenance requirements are minimal compared to forced-air systems.

Periodic checks of pumps, valves, and controls ensure optimal performance. Water quality management prevents corrosion and scaling, preserving efficiency.

Manufacturers such as Danfoss provide detailed documentation, including the danfoss underfloor heating manual, which outlines commissioning, troubleshooting, and maintenance best practices.

Control Systems and Smart Integration

Modern hydronic systems embrace digital intelligence. Smart thermostats, mobile applications, and building management systems enable granular control and remote monitoring.

Weather compensation adjusts flow temperatures based on outdoor conditions, enhancing efficiency. Occupancy sensing further refines energy use, ensuring heat is delivered only when and where needed.

These technologies transform underfloor heating from a passive system into an adaptive thermal network.

Health and Comfort Implications

Radiant heating improves indoor air quality by reducing air movement and dust circulation. This benefit is particularly valuable for individuals with allergies or respiratory sensitivities.

Even heat distribution eliminates cold spots and drafts. Surface temperatures remain comfortable, reducing the need for excessive clothing or localized heaters.

The psychological effect of warm floors should not be underestimated. Thermal comfort contributes to overall well-being and perceived quality of space.

Commercial and Institutional Applications

Beyond residential use, hydronic underfloor heating is widely deployed in schools, hospitals, museums, and commercial buildings. Large open spaces benefit from the system’s ability to deliver uniform heat without visual intrusion.

In heritage buildings, underfloor heating preserves architectural integrity while improving comfort. Low-temperature operation protects sensitive materials and artifacts.

Economic and Property Value Impact

Homes equipped with hydronic underfloor heating often command higher market value. Buyers increasingly prioritize energy efficiency, comfort, and sustainability.

While resale value varies by market, the presence of a well-designed hydronic system is generally perceived as a premium feature, particularly in colder climates.

Design Considerations and Best Practices

Successful implementation begins with integrated design. Insulation quality, floor buildup, and heat loss calculations must align with system capabilities.

Poor design can undermine performance, regardless of component quality. Collaboration between architects, engineers, and installers ensures optimal outcomes.

Attention to detail during design mitigates common issues such as uneven heating or excessive response times.

Future Developments in Hydronic Heating

Innovation continues to refine hydronic technology. Advances in materials science, control algorithms, and renewable integration are expanding possibilities.

Ultra-thin systems simplify retrofits. AI-driven controls optimize performance dynamically. Hybrid energy systems enhance resilience.

As buildings become smarter and more sustainable, hydronic underfloor heating is positioned as a foundational technology rather than a niche solution.

How It Works

- Heat Source: A boiler (gas, oil) or a heat pump (air-to-water, geothermal) heats water.

- Distribution: The heated water travels through a network of PEX pipes, often embedded in concrete or under flooring, guided by a manifold.

- Radiant Heat: The warm pipes heat the floor, which then radiates warmth upwards into the room.

- Control: A thermostat monitors room temperature, telling the system when to turn on/off or adjust water flow for zone control.

- Return: Cooled water returns to the heat source to be reheated in a closed loop.